Your generation ships will have 99 problems. Food and fuel won't be two of them.

Food won't be a problem if you like fish.

Fuel is a bit trickier, and requires command staff to know at the outset that their nuclear carrier is now a generation ship. Let's pause to look at the nuclear ship refueling cycle.

The refueling cycle

When a reactor shuts down, nuclear fuel keeps making heat. Civil reactors handle their fuel "wet". CanDU and RBMK have removable plugs that allow machines to swap fuel rods while the reactor is underway, and it's kept wet in the machine. BWR/PWR/VVER types, you have to shut down and pop the lid off, and the spaces above the reactor lid are a huge pool that you flood. (e.g. the worrisome fuel pool in Fukushima reactor 4). That's how you manage decay heat.

With military reactors, there's no space for that. So you must wait a long time for the fuel to cool enough to even start your refueling operation, so you use that time to do a systems overhaul as well. This whole deal takes 3 years.

So. Suppose your ship is on year 25 and the drydock is ready. But wait! War is imminent in the next 1-3 year; you'd be caught in drydock. That won't do. So your refueling/overhaul is deferred. In year 27 war begins, you see robust action through year 32, but no overhaul yet: another boat needs it more due to battle damage. So year 35.

Also, suppose on year 35 they have been idling for 12 hours and suddenly they gotta go Right Now. That reactor will in a Xenon Pit. So it'll be built with the control-rod "authority" to quickly blow through it and regain full power, without resorting to safety violations like Chornobyl. We're talking a lot of reactivity and rod authority that will keep it going when it doesn't have a xenon pit.

Military reactors are sized for contingencies.

Getting to 150 years

Nuclear fuel is pretty simple: fuel burnup is proportional to the heat energy you use. Carrier reactors are sized for a career of high tempo maneuvering: lots of fast cruise and generous use of energy since it's plentiful.

If you can reduce power consumption, your reactor lasts longer in proportion. Making it to 150 years takes about an 80% cut in energy usage. Obviously you will be quitting flight ops, and minimizing sea cruise. Keeping propulsion at tickover, just enough to maintain sea stability, or weighing anchor somewhere, will be key. Then you cut down your electrical loads and reduce your heating loads with good insulation (which you didn't really need before).

I would expect that most of the time, one of the two reactors would be shut down. The ship is more than capable of fighting on one reactor, so it should be able to serve in "generation ship" mode with one reactor at low power.

The experience of the civil nuclear industry is that reactors age quite well. There haven't been an appreciable number of new US plants since the 1980s, so they're all quite old - and yet they are repeatedly recertified, even in a post Chornobyl post Fukushima age. The only major difference is that carrier reactors use salt water as an ultimate heat sink in heat exchangers, and corrosive salt water may be an issue.

One option to slow or arrest salt water corrosion is for the carrier group to relocate to a river which allows them to sail sufficiently upstream to be in fresh water. As discussed, this would be one of their 99 other problems.

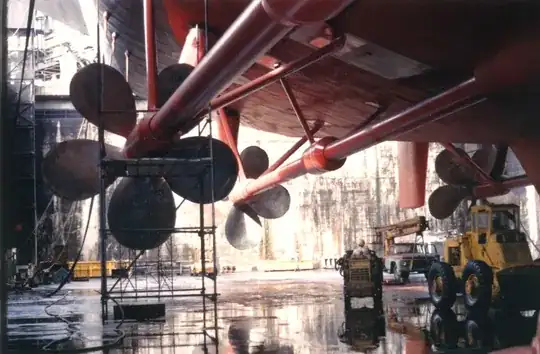

One way to deal with hull maintenance is to use bulldozers, tides and pumps to make a man-made basin, and an improvised "lock" made by pushing dirt around. Float the carrier into the "lock", fill the lock and basin, float the carrier into the basin, then open the "locks" and let the carrier settle onto the earth - the equivalent of blocks in a drydock. Then, to reach the carrier bottom, you tunnel the dirt out from under the carrier, in narrow strips of maybe 20 feet wide, so 90% of the carrier bottom is still supported by earth. You remove barnacles and replace the bottom antifouling, and when it cures, refill that tunnel and dig another tunnel. You could do this in a continuous "bubble", digging out on the aft side of the tunnel and repacking the dirt in the forward side. When the process is done, have the bulldozers re-create the "lock", pump the basin full of water, and float the carrier back to sea.