In light of SpaceX's recently winning the contract to go to the moon for NASA, I started thinking (again) about what avenues sending a rocket that size might open in our near-future. So for a short story I'm writing, I'm building a first base on the moon.

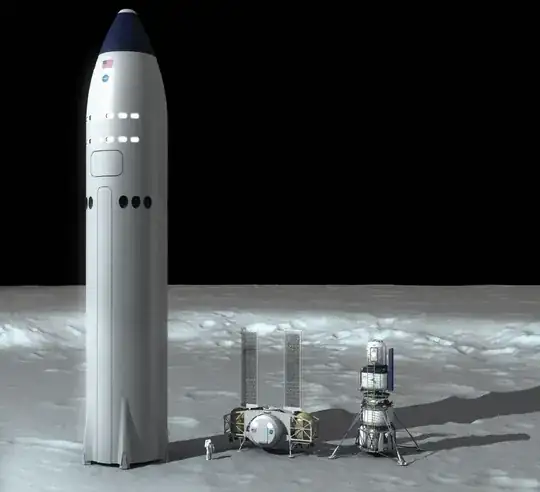

SpaceX's vehicle (do I need to say this) is the one on the left. Yes, that thing is big, ten story building big, and with (multiple rounds of) in-space refueling, and expendable launchers (use them to build your first habs on the moon), we can send about 100 tons to the moon each time. SpaceX is making sounds (through their CEO) that suggest a build/launch marginal cost (i.e. ignoring initial R&D) of about USD \$5-10M. It's still not "dirt-cheap", mind you but at that cost, NASA, SpaceX or whomever hires them to do so can afford to send a lot of mass. (For scale relative to the enormous US economy, US defense budget in 2021 was USD \$733 billion, so a fleet of 100 starships at the price mentioned above would be less than 0.2% of that).

Now, to set up my first smelter/factory, how much mass would I need? Let's put a very low bar in place and say it needs to be able to process 1 ton of material per day. For comparison, a rather primitive ore smelter with late 1800's technology could process 20,000 tons per day. But you know, we're in space. Stuff is a bit hardercitation needed there. So we'll make allowances by reducing production several thousand-fold. Still if you think about it, even being able to produce 1 ton of stuff, say aluminum rods or iron bars, per day, would dramatically reduce habitat construction costs on the moon, since each ton you produce locally is a ton you don't have to schlep around expensively from Earth, and especially for bulk materials, that seems to make a lot of sense to get going as soon as humanly feasible.

So, how small can this kind of setup be, in terms of mass?

You can get maybe 300 watts per square meter out of solar panels on the moon, only slightly more than on Earth. It takes 13 kilowatt-hours for the best smelters on Earth to make 1 kg of aluminum. So to make that one aluminum bar you're going to need about 43 square meters of panels.

Lunar homesteaders are going to find themselves very quickly looking for a nuclear reactor.

– stix Apr 23 '21 at 20:15